Why Speed Will Define Europe's Defense Advantage

Discover how SPREAD’s Engineering Intelligence helps Defense Primes and National Defense Authorities cut time to capability and strengthen digital sovereignty.

Europe is experiencing a Zeitenwende – a turning point in its defense posture. Amid rising geopolitical tensions and rapidly expanding budgets, defense Primes face mounting pressure to deliver faster and at scale. They must move from bespoke project work to scalable series production – all while accelerating development and delivery timelines.

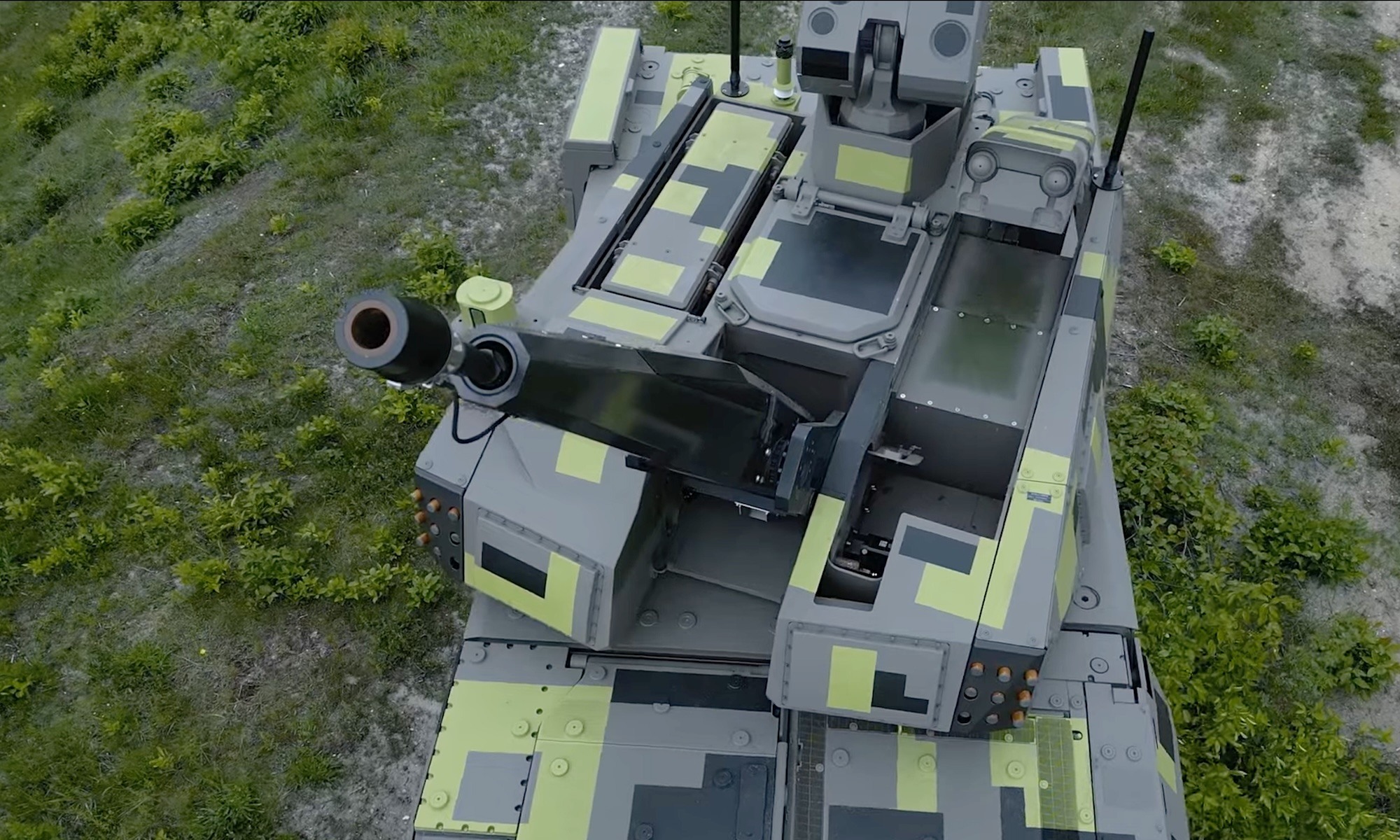

At the same time, the sector is undergoing a structural shift toward software-defined defense. Programs like MGCS and FCAS are no longer theoretical – they signal a new paradigm: software-defined, modular, upgradeable, and interoperable platforms designed for long-term adaptability and cross-national integration. Hardware remains essential. But software now defines capability.

Software-defined defense means building modular, upgradeable systems where software drives performance, interoperability, and adaptability.

The challenge? Traditional engineering methods – fragmented toolchains, Excel-based processes, and disconnected data – are not built for the pace or complexity of today’s requirements.

Requirements often arrive in unstructured formats – PDFs, spreadsheets, or fragmented documents – reconciled manually across teams. Prior platforms and architectures are rarely reused. Each RFQ initiates a siloed development effort. As system complexity grows, interdependencies between mechanics, electronics, and software exceed what any spreadsheet – or team – can reliably track. Troubleshooting becomes slow, reactive, and expert-dependent.

The result: delayed quotes, missed reuse potential, bloated timelines, and ever-expanding complexity.

The impact? Lost contracts. Missed delivery deadlines. And diminished readiness in the field.

Even mature PLM infrastructures are often not enough. They were never designed to dynamically integrate unstructured requirements, variant configurations, and complex system interdependencies. Without a connected layer of engineering intelligence, they struggle to manage today’s velocity and complexity.

Leading defense Primes are rethinking how they engineer, from quote to deployment. Rather than relying on fragmented systems and isolated teams, they’re adopting Agentic Engineering Intelligence – On-premise with modern security features.

At the core of our solution is the Product Twin – a live, interactive representation of a defense system. But how is it built and utilized?

Rapid Ingestion: SPREAD automatically integrates and contextualizes data from PLM, CAD, Excel, PDF, E/E architectures, and more – structured and unstructured – across mechanics, electronics, and software.

Product Twin: That data becomes a contextualized model of ECUs, functions, signals, and requirements – searchable, traceable, and visualized in 2D/3D across variants.

Action Cloud: On top of the twin, SPREAD deploys intelligent pre-configured applications that power cross-functional workflows and collaboration – RFQ management, architecture management, error troubleshooting, onboarding, and more. Beyond that, customers can easily build their own applications in a low-code environment.

This is not another siloed tool. It’s a layer of intelligence that makes existing data, systems, and processes smarter – without needing to replace them.

Proven at scale in the automotive sector, where leading OEMs like Volkswagen, Mercedes-Benz and BMW use our platform to manage development complexity, secure SOP timelines, and reduce costs – SPREAD is now bringing its Agentic Engineering Intelligence to the defense sector. The mission: enable defense Primes and Armies to collaborate seamlessly, move faster, and build better systems through a shared, data-driven engineering foundation.

The Product Twin helps Primes accelerate the quotation process, shorten development times, reduce variant complexity, and enable error troubleshooting. But it also becomes the interface between defense Primes and armies. Armed forces can visualize the impact of their requirements in real time, iterate with engineering teams faster, troubleshoot in the field and train before delivery. This tight feedback loop improves speed, accuracy, and mission readiness across development, field diagnostics, and onboarding.

Program Leaders – Cut Through Requirement Chaos to Quote and Develop Faster

National armies are issuing more RFQs with shorter response windows. Yet each one differs – arriving in disconnected formats and requiring manual reconciliation. Without structured traceability or portfolio context, engineering teams fall back on manual quotation and custom-built solutions, increasing time, cost, and program risk.SPREAD’s Product Twin automatically parses incoming RFQs and links them to historical designs, highlighting reuse potential and variant deltas. This shortens the quote cycle and supports modular development – enabling faster delivery, reduced cost, and fewer redundant variants.

Field-Service Leaders – Minimize Downtime, Maximize Readiness

In the field, repair time equals readiness. Modern systems are highly interdependent, making diagnosis slow and complex. Many technicians still rely on paper manuals, outdated documentation, or limited expert input. Errors remain unresolved longer, reducing mission availability. SPREAD provides a VIN-specific 3D/2D Product Twin, giving field teams and technicians real-time views of the exact system configuration. Suggested root causes, linked error paths, and step-by-step repair guidance accelerate resolution – boosting repair speed and operational readiness.

Training Leaders – Onboard Soldiers Before the System Ships

Onboarding is a persistent bottleneck. Training programs often depend on physical units, live instructors, or paper-based manuals – resources that are delayed or in limited supply. The result is a lag between delivery and deployability.

SPREAD enables interactive, remote training directly on the Product Twin – well before hardware is delivered. Soldiers learn on the exact system variant they will operate, guided by intuitive visualizations, embedded knowledge, and task-specific workflows. The result: faster ramp-ups, earlier force readiness, and earlier revenues for Primes.

SPREAD is already embedded at leading Defense Primes in Europe. One leading OEM reduced time-to-market by 20%, accelerated error resolution by 60%, and enabled soldier onboarding before vehicle delivery.

Building the future of defense starts with the infrastructure that makes it possible – talk to a Defense Expert at SPREAD.

Why Speed Will Define Europe's Defense Advantage

Discover how SPREAD’s Engineering Intelligence helps Defense Primes and National Defense Authorities cut time to capability and strengthen digital sovereignty.

Read More

How Rheinmetall Air Defence improved change impact analysis - with a Defense Digital Twin

Revolutionize defense with SPREAD’s Defense Digital Twin: Unify data, optimize change impact, and accelerate innovation. Discover breakthrough efficiency!

Read More

Inside the Industrial AI Summit 2025: What Europe’s Leaders Agreed Must Happen Next

At the Industrial AI Summit 2025, leaders showed how fixing data foundations is key to scaling Industrial AI across Europe’s manufacturing sector.

Read More