Connect field data to boost Aftermarket services

Integrate field and product data to trace root causes, analyze variant-specific issues, and improve diagnostic accuracy for better service outcomes.

What can you achieve with this use case?

Trusted by

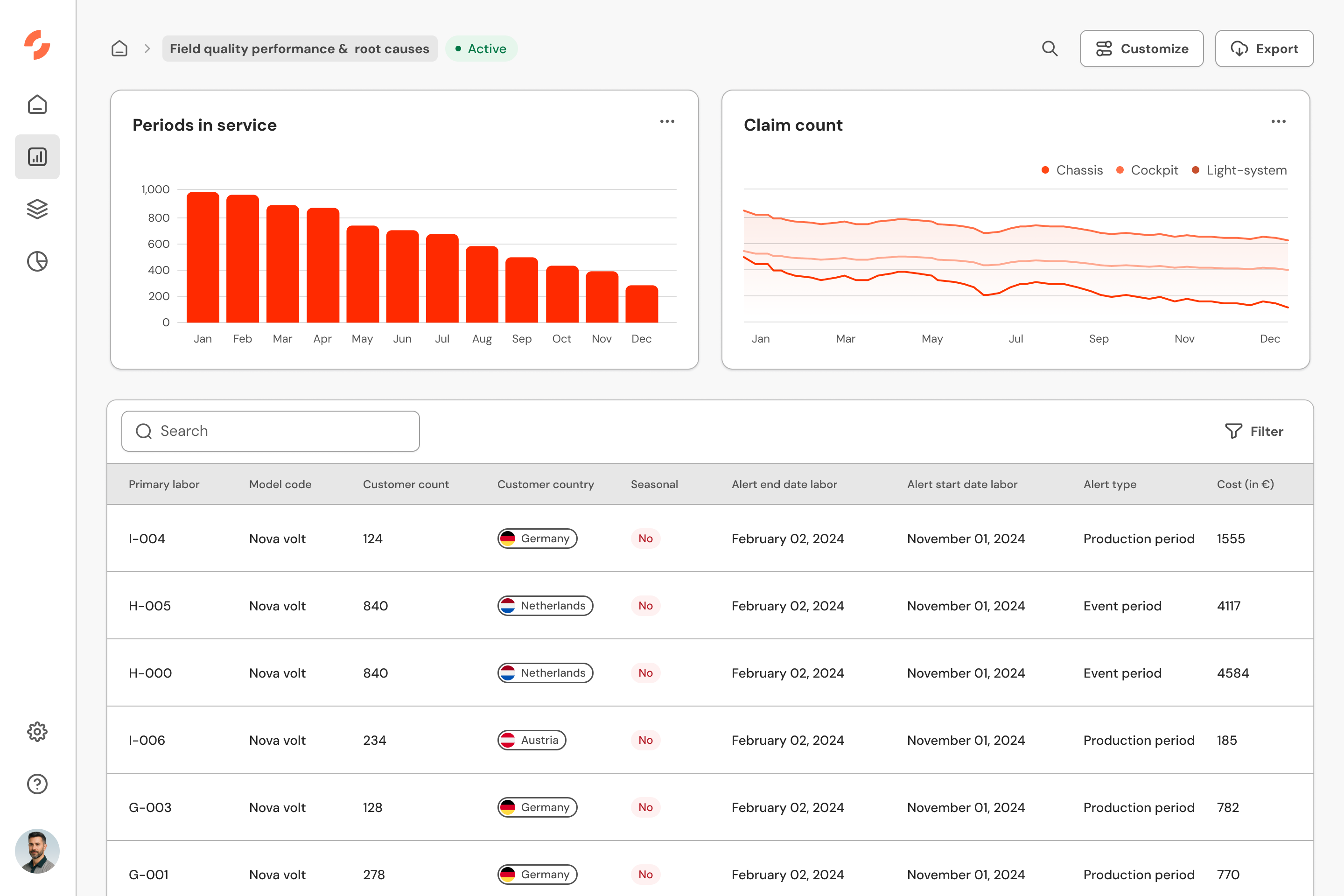

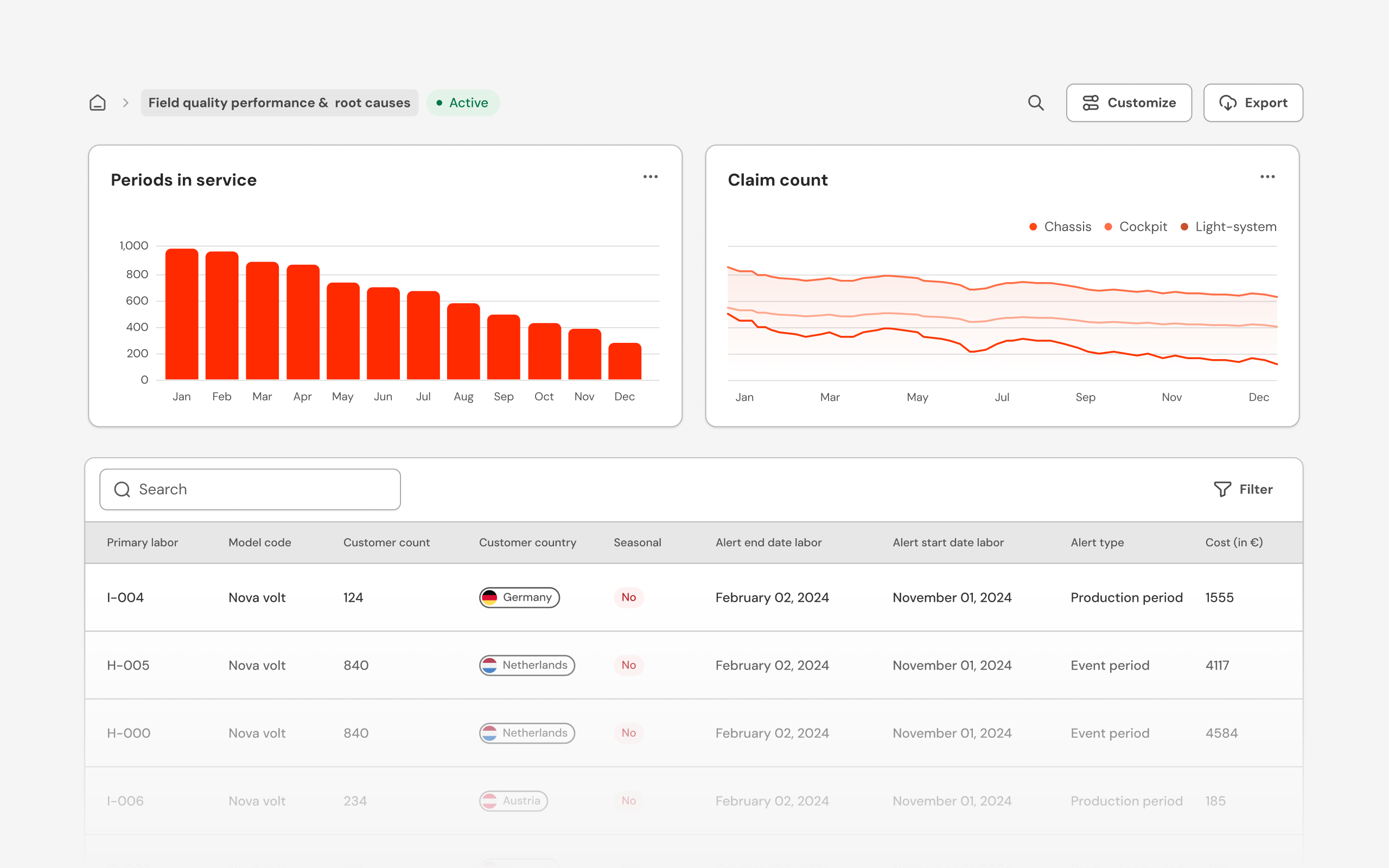

Connect field data to boost services

Gain full visibility into fleet performance and warranty claims with real-time insights. Track failure patterns, service events, and root causes to optimize aftermarket operations and reduce costs.

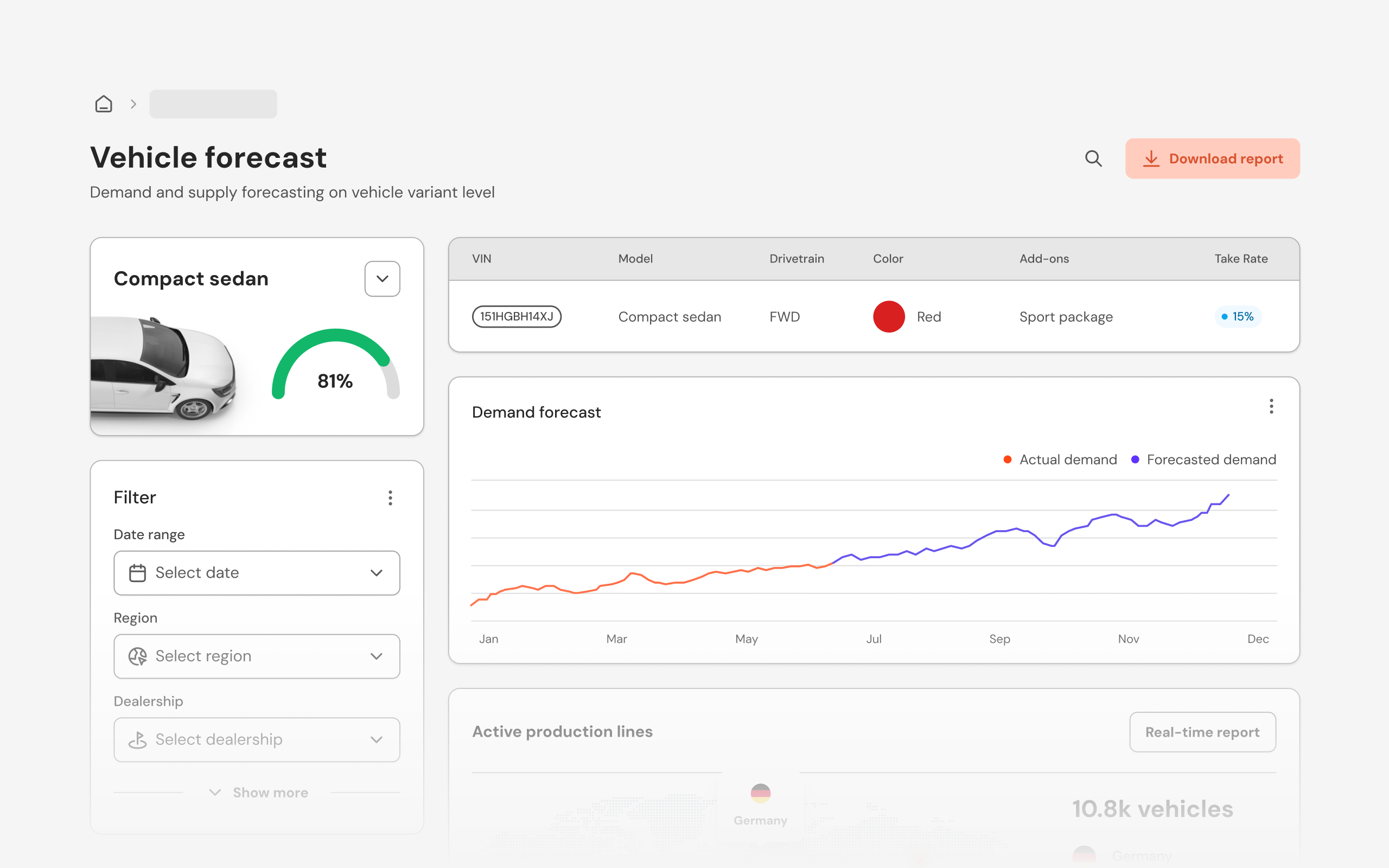

Optimize supply and demand alignment

Optimize inventory with real-time demand forecasting at the vehicle variant level. By analyzing take rates, regional trends, and production activity, aftermarket teams can align supply with market demand, reducing excess stock and improving profitability.

Trace changes and dependencies

Enable full traceability of changes and their impact across dependencies. By integrating data from multiple sources, aftermarket teams can track, prioritize, and manage modifications effectively.

What types of data does SPREAD connect and analyze?

SPREAD integrates critical Aftermarket data from multiple systems and unstructured sources to provide complete traceability from issues to root cause. It connects and contextualizes:

| Data Type | Description | Typical sources | File Formats needed |

|---|---|---|---|

| Wiring-harness topology | Pin-to-pin connectivity, module & connector part-numbers, wire colours/lengths, splice & ground points – the backbone for path-finding and VIN filtering. | Harness engineering (KBL/VeC authoring tools, PDM) |

.kbl

.vec

.xml

|

| BoM + configuration codes | 150 % parts list plus variant / feature codes that let Inspector cut the harness to the exact VIN build. | ERP / MES / BoM databases |

.xls(x)

.csv

.xml

|

| Aftermarket & Service Data | Repair history, service records, maintenance logs, spare part replacements, failure rates, warranty claims, cost tracking, OTA software updates, calibration records. | Company specific system |

.json

.xml

|

| Geometry & schematics | Lightweight 3D shell, optional harness JT, and 2D wiring diagrams (pins, grounds, splice nodes) for visual drill-down from vehicle to wire. | CAD/PDM for 3D, wiring-diagram authoring |

.jt

.svg

.pdf

.png

|

How to

get started

1

Jointly scope

use cases

We bring practical expertise to understand your challenges and scope the right solutions with you.

2

Deploy solutions

rapidly

Within weeks we deploy our platform, integrate the required product data and configure the defined solutions.

3

Rollout across

the company

We train users across teams, scale company-wide, and support you continuously on the way.