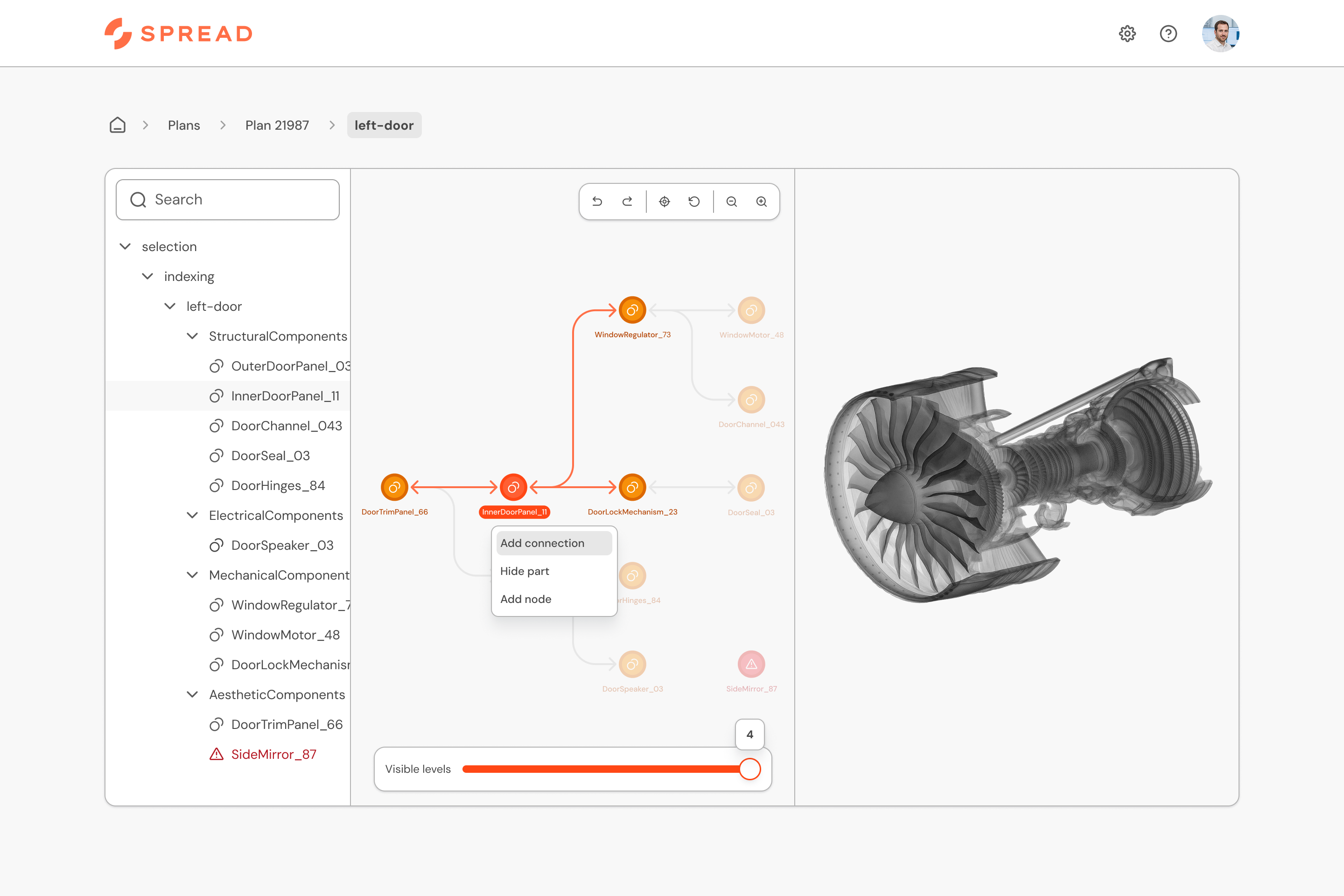

Design production-ready system architectures

Determine and optimize assembly steps using algorithm-based priority graphs based on the geometry of 3D CAD models.

What can you achieve with this use case?

Trusted by

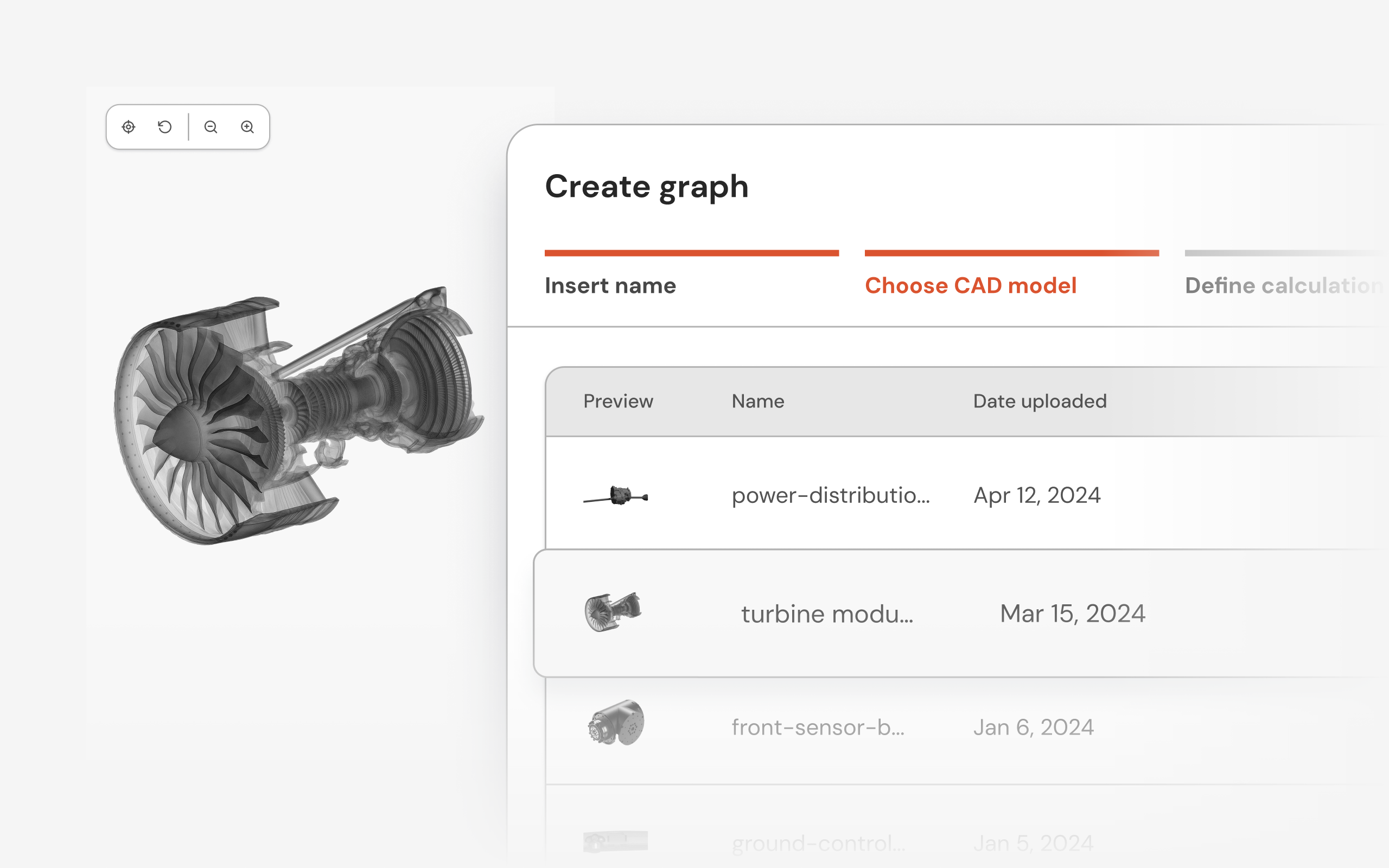

Import CAD Models and product data

The solution requires a CAD model as input, extracting product and BOM data from integrated systems or allowing users to define assembly groups. This forms the foundation for automated assembly planning.

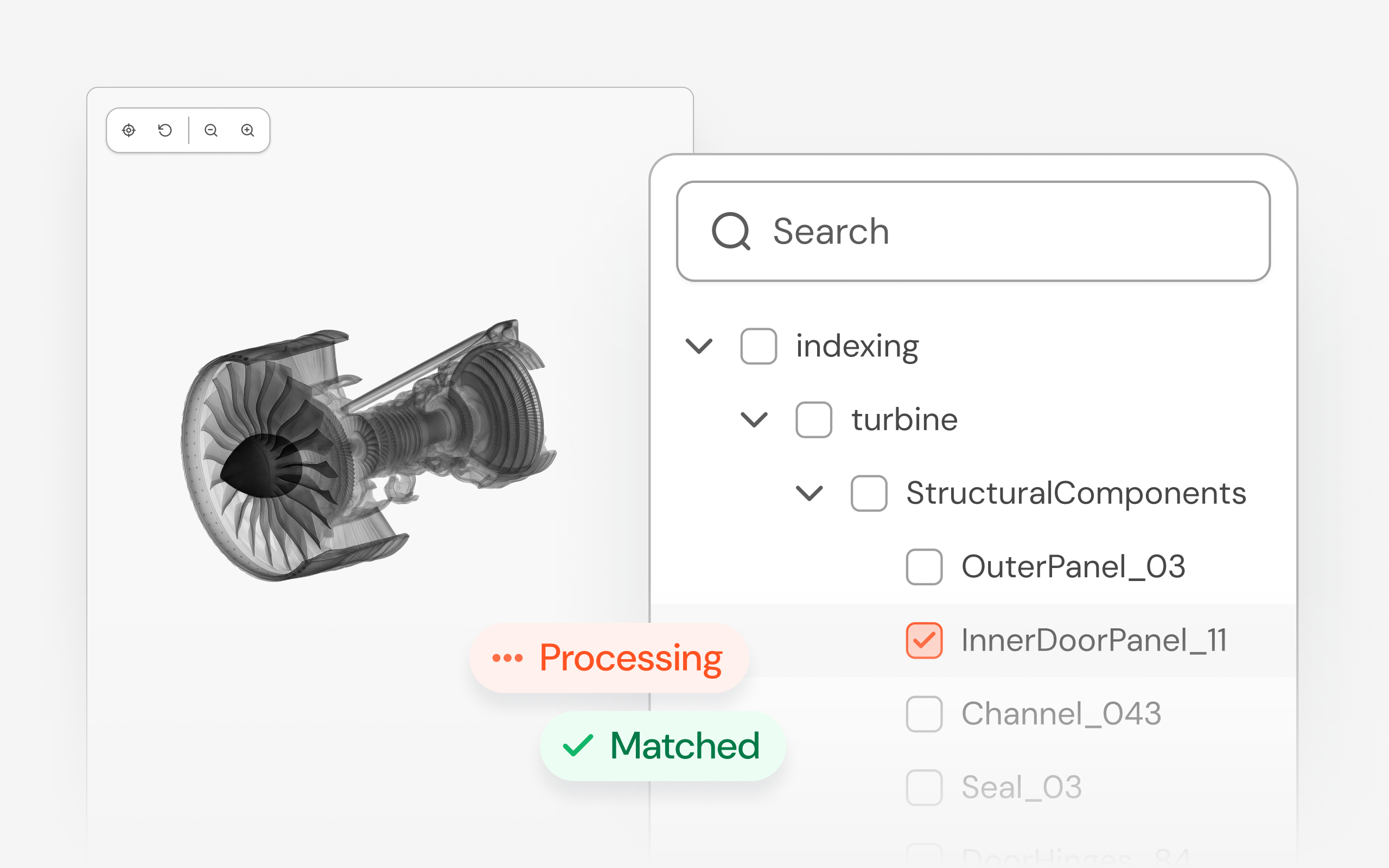

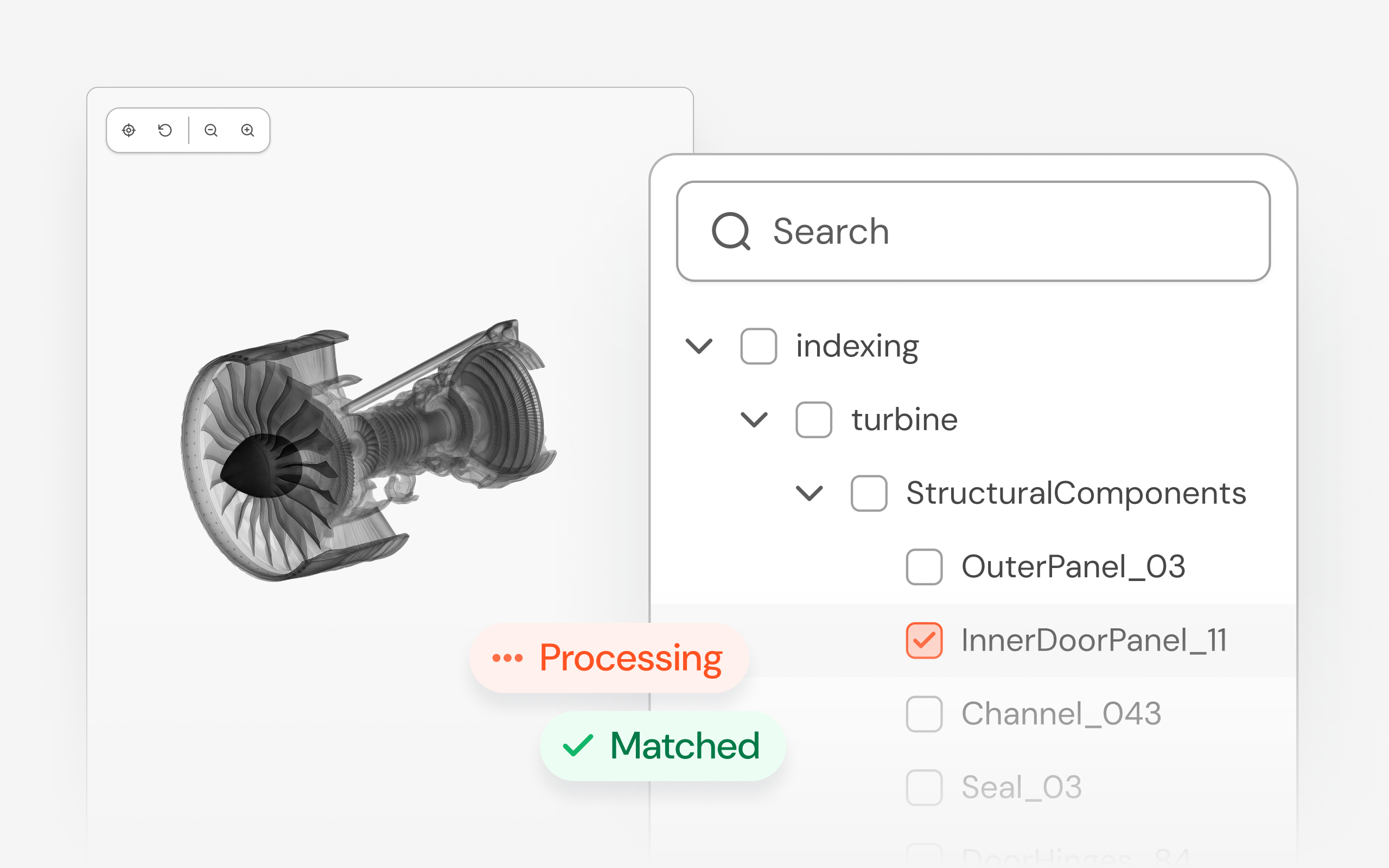

Generate optimized precedence graph

Provide the start node and any optional constraints, such as last parts or specific part orders. Our AI-algorithm will handle the rest, calculating geometrically reasonable assembly dependencies by analyzing the 3D data.

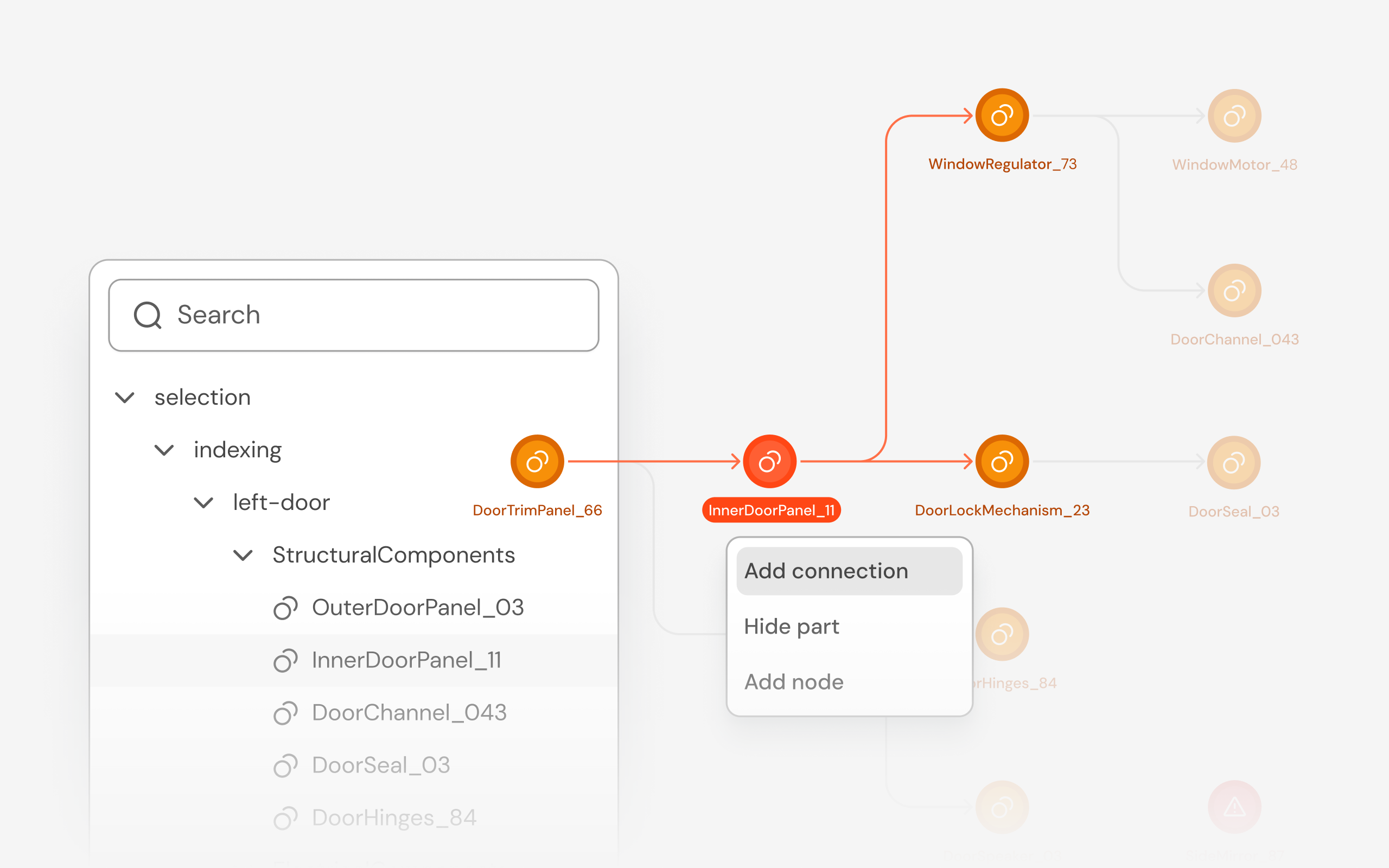

Adapt precedence relations

In the web solution, you can validate the calculated precedence relations directly using the interactive 2D graph view, which is condensed to a view relevant for production. Dependencies can there be adapted if the algorithm missed any and view all parallel and sequential assembly steps.

Get an instant tour

See how SPREAD turns complex product data into clear, actionable insights. Take a quick tour and see how this solutions deliver impact.

Get an Instant Tour

What types of data does SPREAD connect and analyze?

SPREAD integrates critical Production data from multiple engineering systems and unstructured sources to provide complete traceability from issues to root cause. It connects and contextualizes:

| Data Type | Description | Typical sources | File Formats needed |

|---|---|---|---|

| CAD geometry | Full 3D part geometries used for assembly planning and dependency analysis. Required to calculate feasible part sequences and optimize the precedence graph. | CAD systems (CATIA, Siemens NX, Creo) |

|

| BoM + configuration codes | List of materials and components needed for precise assembly planning incl. 150 % parts list plus variant | ERP / MES / BoM databases |

|

| CAD geometry | Full 3D part geometries used for assembly planning and dependency analysis. Required to calculate feasible part sequences and optimize the precedence graph. | CAD systems (CATIA, Siemens NX, Creo) |

.jt

.step

.stl

.iges

.3dxml

|

| BoM + configuration codes | List of materials and components needed for precise assembly planning incl. 150 % parts list plus variant | ERP / MES / BoM databases |

.xls(x)

.csv

.xml

|

How to

get started

1

Jointly scope

use cases

We bring practical expertise to understand your challenges and scope the right solutions with you.

2

Deploy solutions

rapidly

Within weeks we deploy our platform, integrate the required product data and configure the defined solutions.

3

Rollout across

the company

We train users across teams, scale company-wide, and support you continuously on the way.