Deliver live repair insights and guidance

Provide tailored repair instructions, variant deltas, and actionable learning paths to improve technician efficiency and reduce service times.

What can you achieve with this use case?

Trusted by

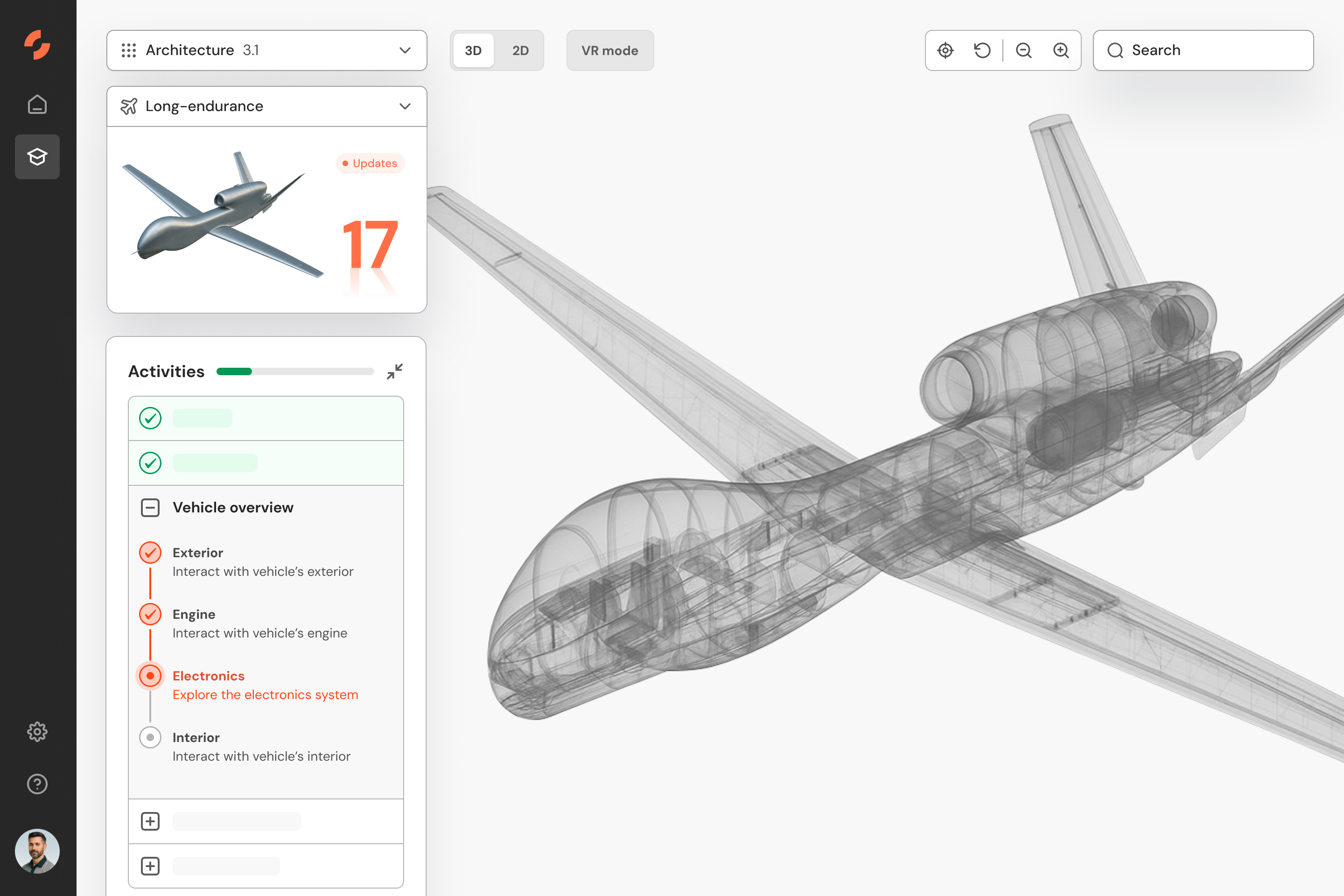

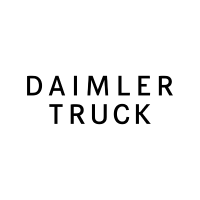

Exploring function- and signal path

Explore function and signal paths at a variant-specific level, showing only installed components and connections for precise and efficient troubleshooting.

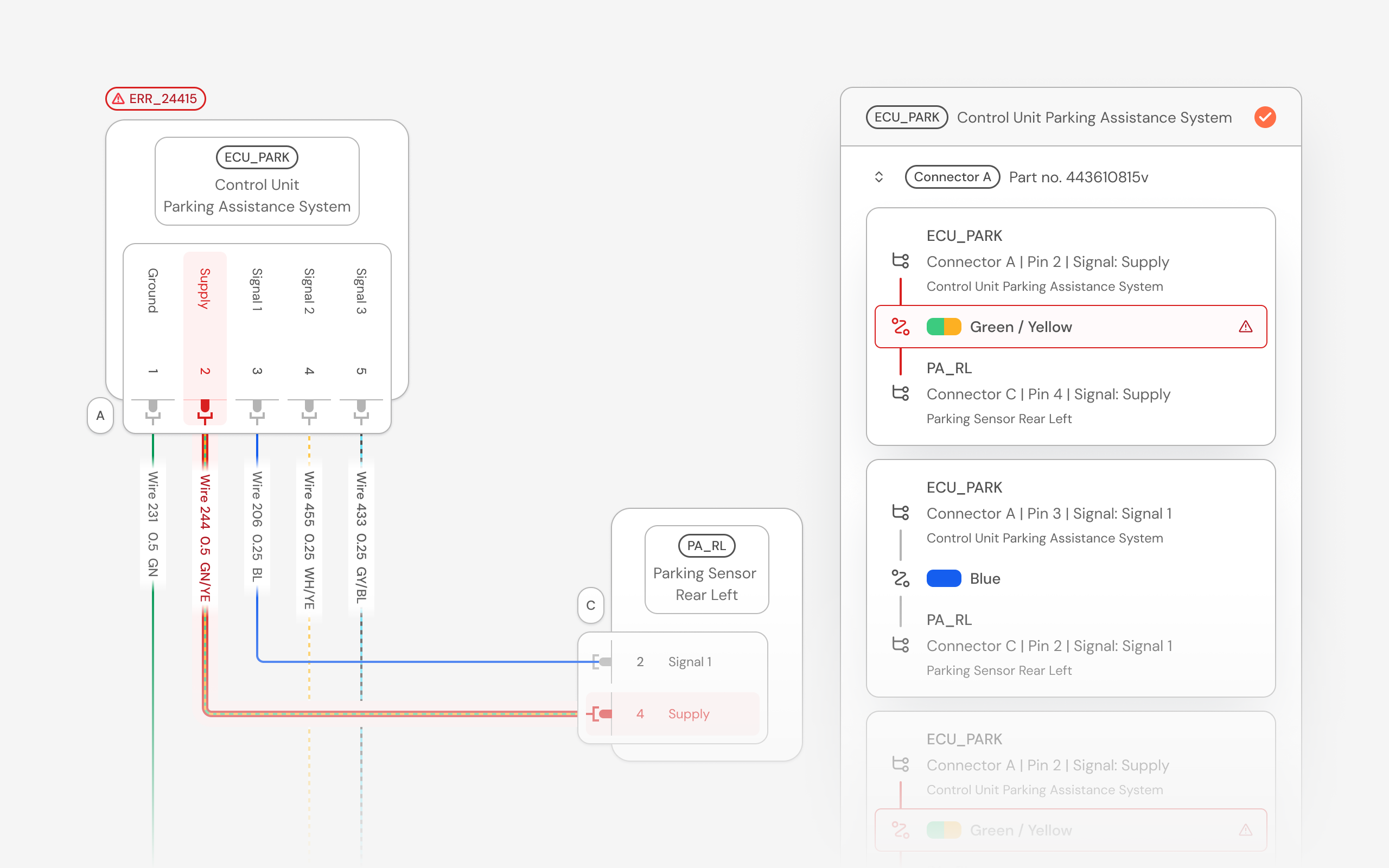

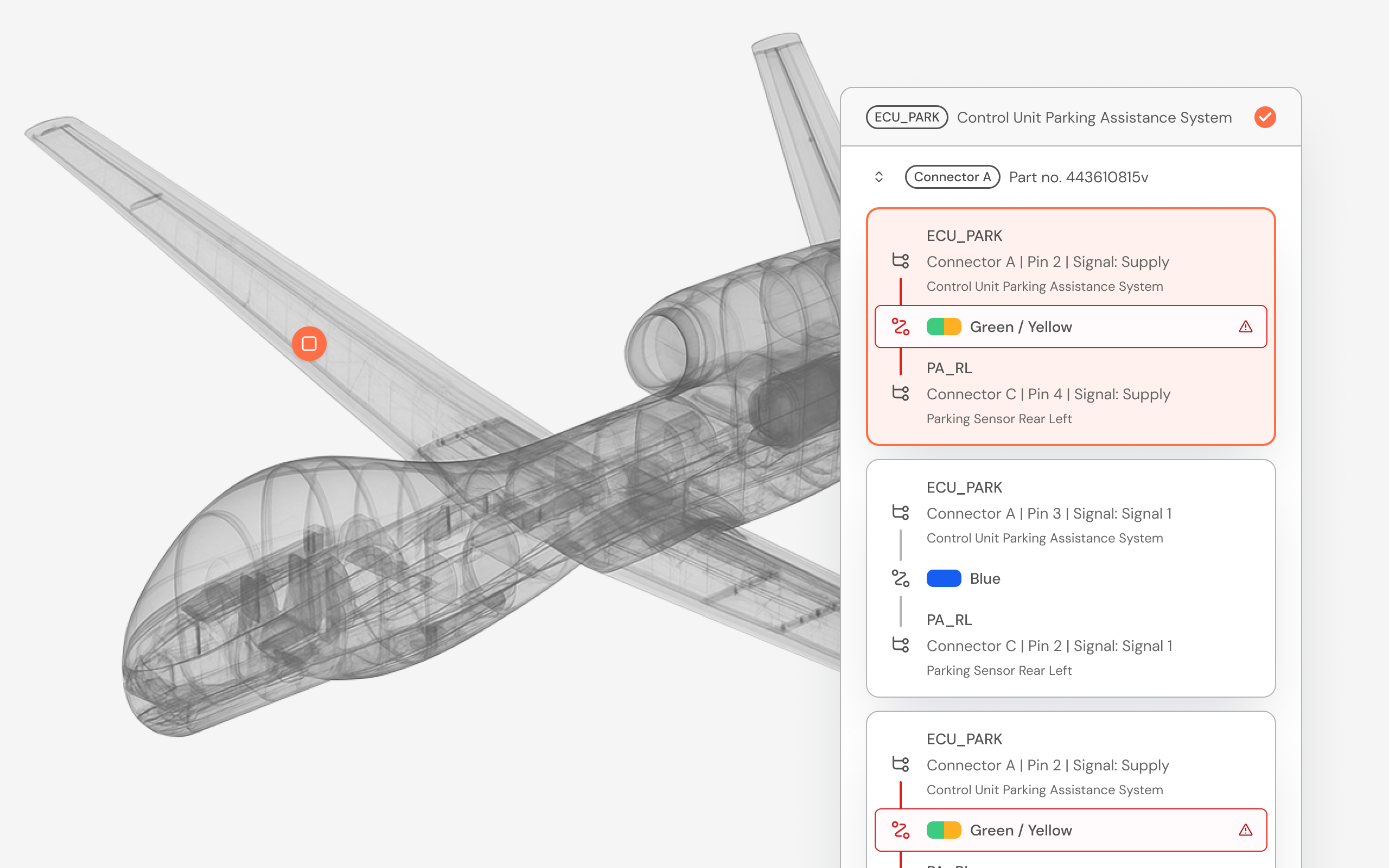

Identifying changes with 3D delta view

The function enables users to compare design or production versions through an intuitive 3D delta view. By highlighting discrepancies and changes directly on the 3D model, it simplifies the identification of impacted components and areas.

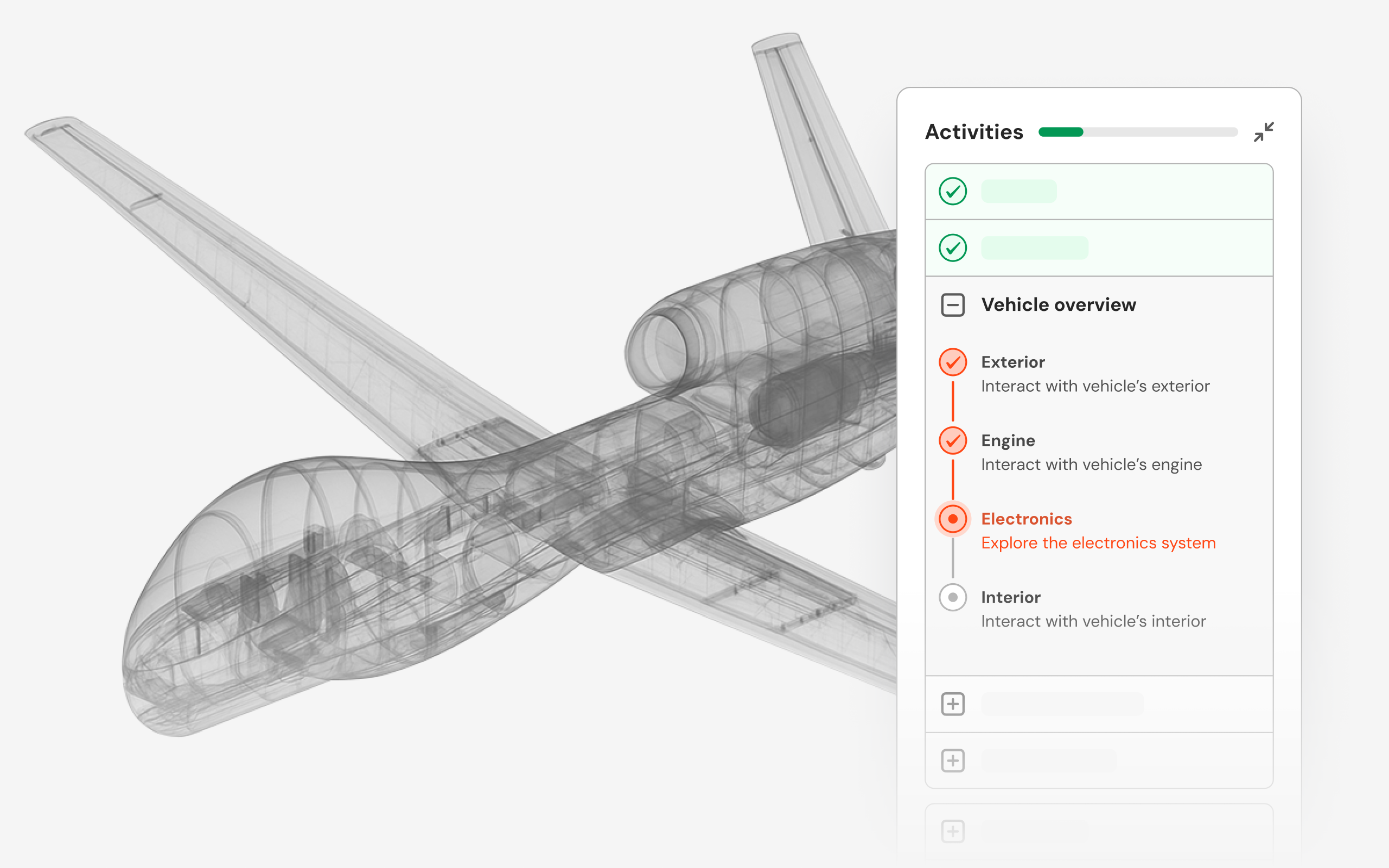

Guiding with learning paths

The learning paths guide users step-by-step through tailored modules, focusing on relevant skills and knowledge. By linking theoretical concepts with practical scenarios, users can deepen their expertise while solving real-world challenges, ensuring effective and focused upskilling.

Get an instant tour

See how SPREAD turns complex product data into clear, actionable insights. Take a quick tour and see how this solutions deliver impact.

Get an Instant Tour

What types of data does SPREAD connect and analyze?

SPREAD integrates critical data from multiple engineering systems and unstructured sources to provide complete traceability from issues to root cause. It connects and contextualizes:

| Data Type | Description | Typical sources | File Formats needed |

|---|---|---|---|

| Wiring-harness topology | Pin-to-pin connectivity, module & connector part-numbers, wire colours/lengths, splice & ground points – the backbone for path-finding and VIN filtering. | Harness engineering (KBL/VeC authoring tools, PDM) |

.kbl

.vec

.xml

|

| BoM + configuration codes | 150 % parts list plus variant / feature codes that let the solution cut the harness to the exact VIN build. | ERP / MES / BoM databases |

.xls(x)

.csv

.xml

|

| Diagnostic test results | Tester log with VIN, station, time-stamp, ECU IDs, triggered DTCs & error texts – the starting point for every investigation. | Company specific system |

.json

.xml

|

| Geometry & schematics | Lightweight 3D shell, optional harness JT, and 2D wiring diagrams (pins, grounds, splice nodes) for visual drill-down from vehicle to wire. | CAD/PDM for 3D, wiring-diagram authoring |

.jt

.svg

.pdf

.png

|

| Mapping & meta-data | Lookup tables linking harness IDs, DTC IDs, ECU addresses, plus diagnosis specs that define error classes and repair hints. | Company specific system |

.xls(x)

.pdx

.odx

|

Engineering success in action

confidently and unlock innovation with SPREAD.

How to

get started

1

Jointly scope

use cases

We bring practical expertise to understand your challenges and scope the right solutions with you.

2

Deploy solutions

rapidly

Within weeks we deploy our platform, integrate the required product data and configure the defined solutions.

3

Rollout across

the company

We train users across teams, scale company-wide, and support you continuously on the way.